- The working table executes only longitudinal movements. Double V guide-ways are laminated with Turcite-B hand scraped to obtain smooth stick-slip free movements.

- The column carries out only crossfeed movements. The column slide is guided by Precision roller linear guides, with C3 grade high precision ball-screws and driven by servo motor.

- The spindle housing carries out only vertical movements. The Y-axis is also guided by Precision roller linear guides, with C3 grade high precision ball-screws and driven by servo motor.

- The flanged cartridge type spindle is supported by 3 pairs of super precision angular contact ball bearings, preloaded and select-fitted into spindle cartridge. The dresser is mounted on right side of table. Auto surface grinding cycles and dressing cycles with compensation are standard.

- The automatic re-circulating lubrication system supplies lubricant to all of the guide ways and lead screws as the machine operates.

- The external independent hydraulic tank is located outside the machine to be easily accessible for maintenance. Driven by the proportional valve hydraulic system for easy speed adjustment in a range of 2~30meter/min for most surface grinding applications

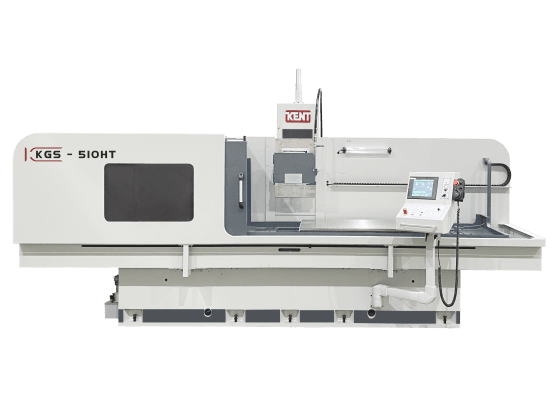

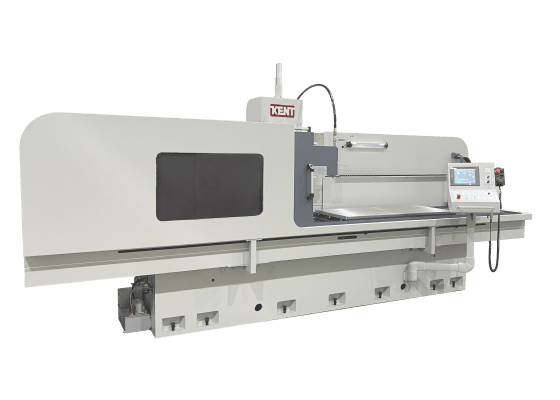

KGS-HT Super Precision Surface Grinder

Model:24HT, 408HT, 510HT, 612HT, 715HT, 820HT

SPECIFICATIONS

| Specification | 24HT | 408HT | 510HT | 612HT | 715HT | 820HT |

| Table working area (mm) | 400×200 | 800×400 | 1000×500 | 1200×600 | 1500×700 | 2000×800 |

| Longitudinal travel (mm) | 550 | 1200 | 1400 | 1600 | 1900 | 2400 |

| Crossfeed travel (mm) | 230 | 440 | 540 | 640 | 740 | 840 |

| Distance from spindle center to table (mm) | 540 | 600 | 600 | 600 | 600 | 850 |

| Wheel dimension (mm) | 255×38×50.8 | 406×50×127 | 406×50×127 | 406×50×127 | 406×50×127 | 508×80×203.2 |

| Table load including magnetic chuck (kg) | 250 | 800 | 1000 | 1200 | 1400 | 2300 |